Environmental Thermal Shock Testing Equipment

Environmental Thermal Shock Testing Equipment Product Introduction:Thermal Shock Test Chamber is used to test the bearin

Basic Info.

| Model NO. | HD-E703 |

| Control | Manual Control |

| Weight | 100-500Kg |

| Power Source | AC220V |

| Damper Device | Forced Air Drived Damper |

| Outside Dimension | 170*235* 182cm |

| Ambient Temperature | 0 Centigrade Degrees to 30centigrade Degrees |

| Controller | Oyo-8226 |

| Cooling Method | Air or Water |

| Available Capacity | 50L, 80L, 108L 216L, 252L, ... |

| Interal Dimension | (W* H* D) 60* 70* 60cm |

| Model | HD-252tst |

| Warranty Period | 12 Months |

| Certificate | ISO9001: 2008 |

| Transport Package | Strong Wooden Case |

| Specification | ISO9001: 2008 |

| Trademark | Haida |

| Origin | China |

| Production Capacity | 150 Sets/Month |

Product Description

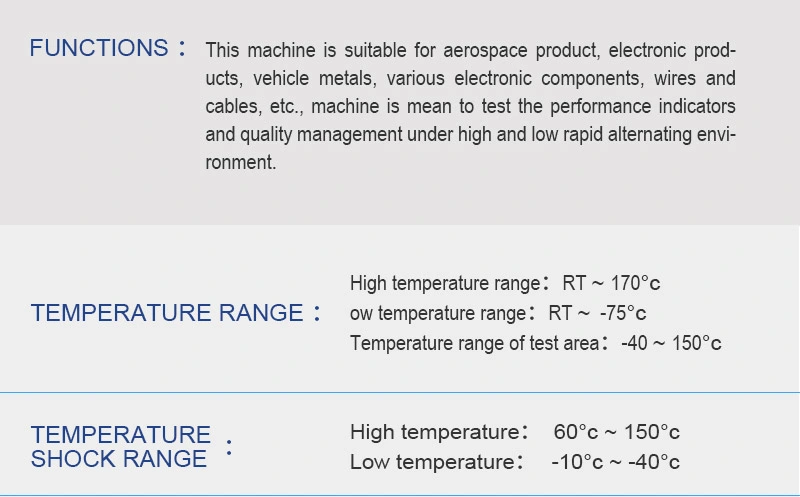

Environmental Thermal Shock Testing EquipmentProduct Introduction:Thermal Shock Test Chamber is used to test the bearing extent of the material structures and composite material in an instant and continuous high temperature and extremely low temperature environment, which is in the shortest time to test its thermal expansion and contraction caused by chemical change or physical harm.The equipment is widely used in metal, plastic, rubber, electronics and other materials and it can be used as an important reference for improving product quality. It meets the standard of MTL, IEC, JIS, GJB…Main Parameters:

| Test method | Pneumatic operated door switch 3 chambers |

| Inner dimension (W*D*H) | 500*450*450mm |

| External dimension (W*D*H) | 1380*1370*1980mm |

| Temperature range | -40 ~ +80ºC |

| High temperature chamber pre-heating range | 60 ~ 100ºC |

| Heating speed | +60→+100ºC about 10 minutes |

| Low temperature chamber pre-cooling range | -65 ~ 0 |

| Cooling speed | Ambient →-65ºC about 65 minutes |

| Temperature deviation | ±3ºC |

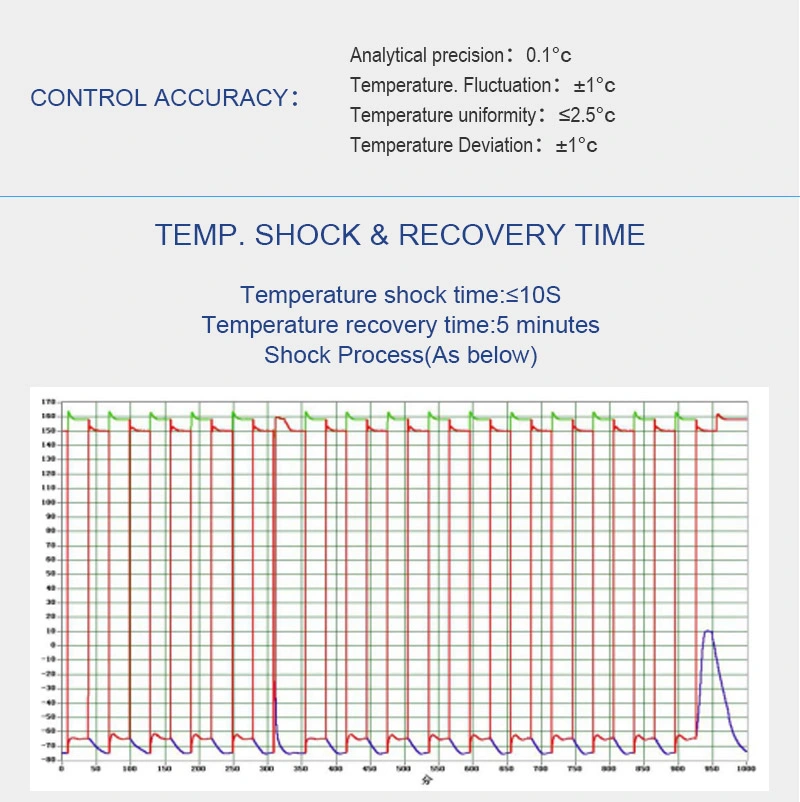

| Thermal recovery time | Within 5 minutes |

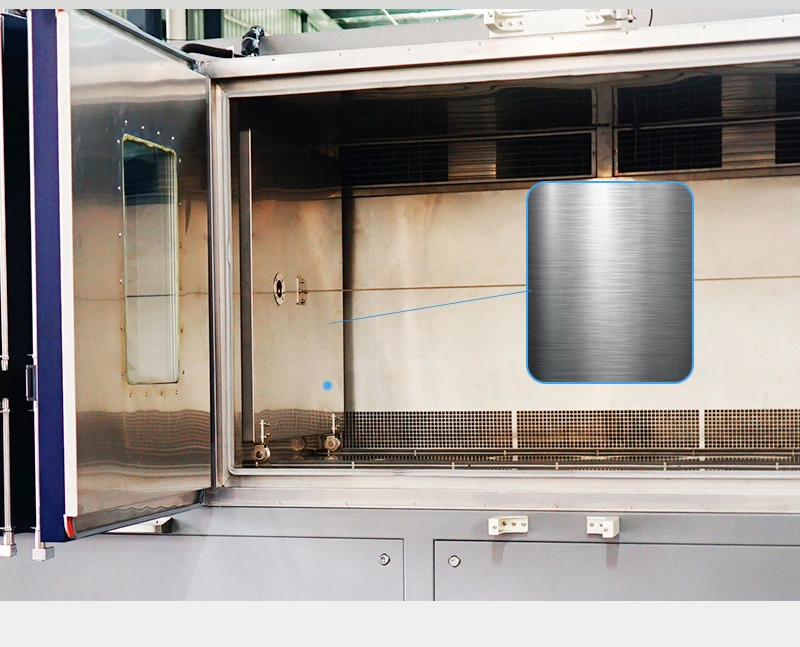

| External material | Antirust processing cold-rolled steel sheet |

| Internal material | SUS#304 stainless steel |

| Thermal insulation material | Polyurethane foam and fiberglass |

| Coolant | R404A / R23 |

| Cooling method | Air cooling |

| Pressure | 0.2 - 0.5Mpa |

| Power supply | Three phase, 380V, 50Hz |

Advantage1.TM 2101 intelligent automatic detection of the operating system, (can adapt to all current PC)2.High-tech, low noise3.Humanized industrial design, easy to place and transport4.The world famous brand core precision components5.Security protection system6.Valid test trip length (modifiable)7.3 seconds fast temperature change

8.2 chambers temperature conversion faster and save time

9.3 chambers in addition to a low temperature test , high temperature test, there can be done at room temperature test

Features:

- Perfect appearance and easy to operate.

- Japan LCD English microcomputer temperature controller, with high memory capacity, can save 100 programs, max 9999 cycles, each cycle max time 999hrs.

- Three chamber structures, high temperature chamber, low temperature chamber and test chamber, control automatically, stay and switch time adjustable.

- Perfect protection alarm functions: short-circuits, Leakage, over temperature of work chamber; compressor over pressure, over load, short water…

- Control interface will display alarm reason and provide check methods, machine has emergency stop button.

- Cold and hot shock temperature recover within 5 minutes, which complies with MTL, IEC, JIS, GJB and other international standards.

- With RS-232C communication port for connecting PC to control, record and save test report.

HAIDA INTERNATIONAL is a professional manufacturer of various kinds of testing equipments over 18 years. HAIDA products are widely used in paper products, packaging, ink printing, adhesive tapes, bags, footwear, leather products, environment, toys, baby products, hardware, electronic products, plastic products, rubber products and other industries, and applicable to all scientific research units, quality inspection institutions and academic fields.

Send to us